LEADER STANDARD WORK

Supervisor Standard Work training develops your front-line leaders’ capability in accelerating improvement & stabilisation of their processes. By re-balancing daily tasks, problem solving and people development, they run today’s production more effectively whilst building processes & people that make ‘tomorrow better than today’.

Overview

Skills developed: effective daily production management & problem solving

Delivery: 5 class-room sessions, one 2-hour session per day (one week)

Practice: developing and testing supervisor standard work during training week

Return on investment: rapid, through immediate application in daily work

Problem solved

The Supervisor Standard Work training program enables organisations to accelerate the transition of their supervisors & team leaders from traditional supervision, characterised by micro-management of shop-floor activities and frequent fire-fighting, to high-performance management, driven by continuous focus on process stability and improvement.

In recent years the role of the supervisor has changed dramatically. They must acquire new leadership skills and improvement capabilities to succeed in today’s environment. They must fit new improvement, training and coaching tasks into their already crammed work schedules. Many supervisors struggle with this.

Skills developed

What participants will be able to do…

improve time management: decide what to focus on and when without neglecting mission-critical activities

balance activities to deliver progress: running production, stabilising & improving processes, developing team capabilities

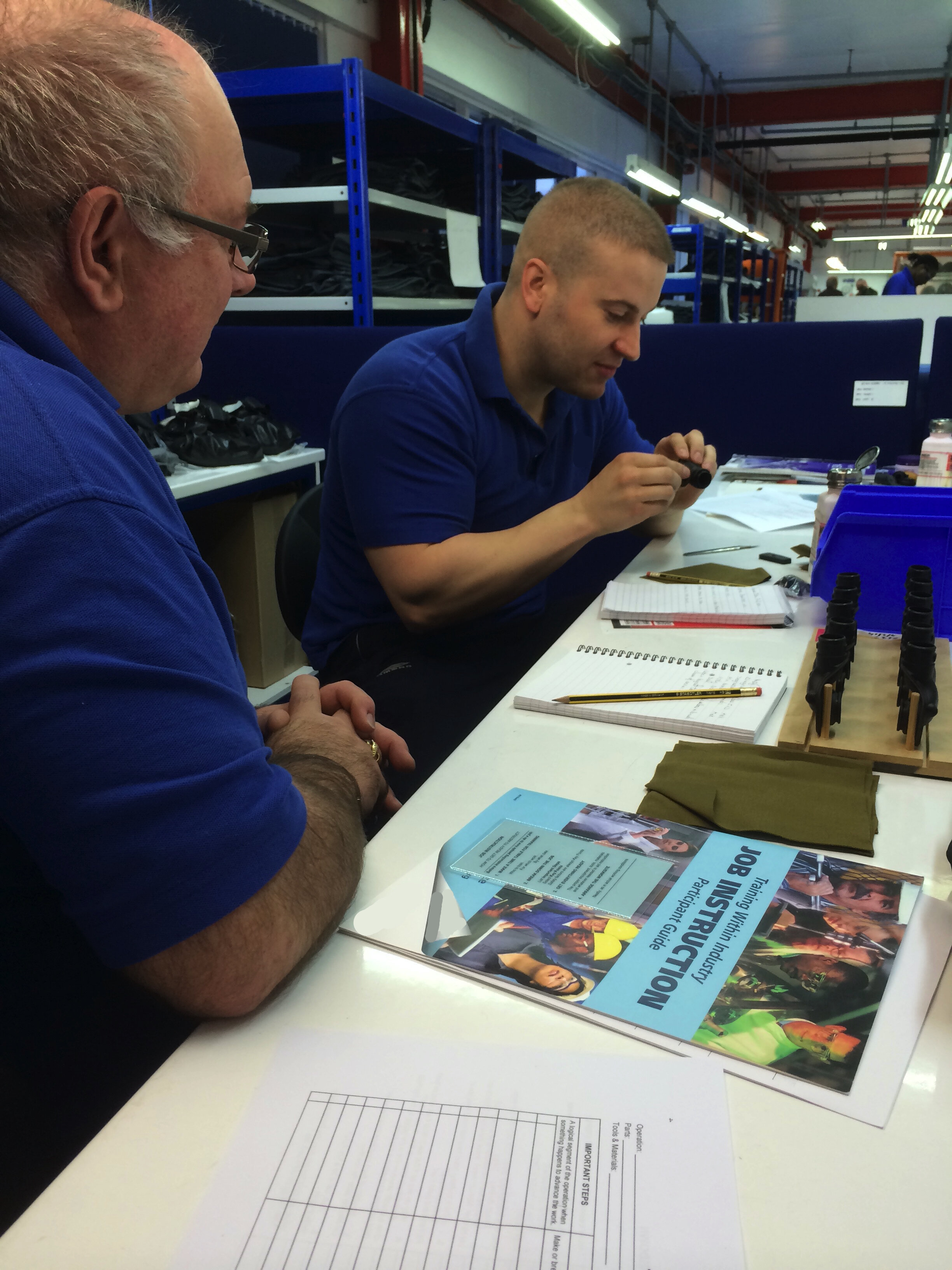

develop standard work instruction for critical tasks

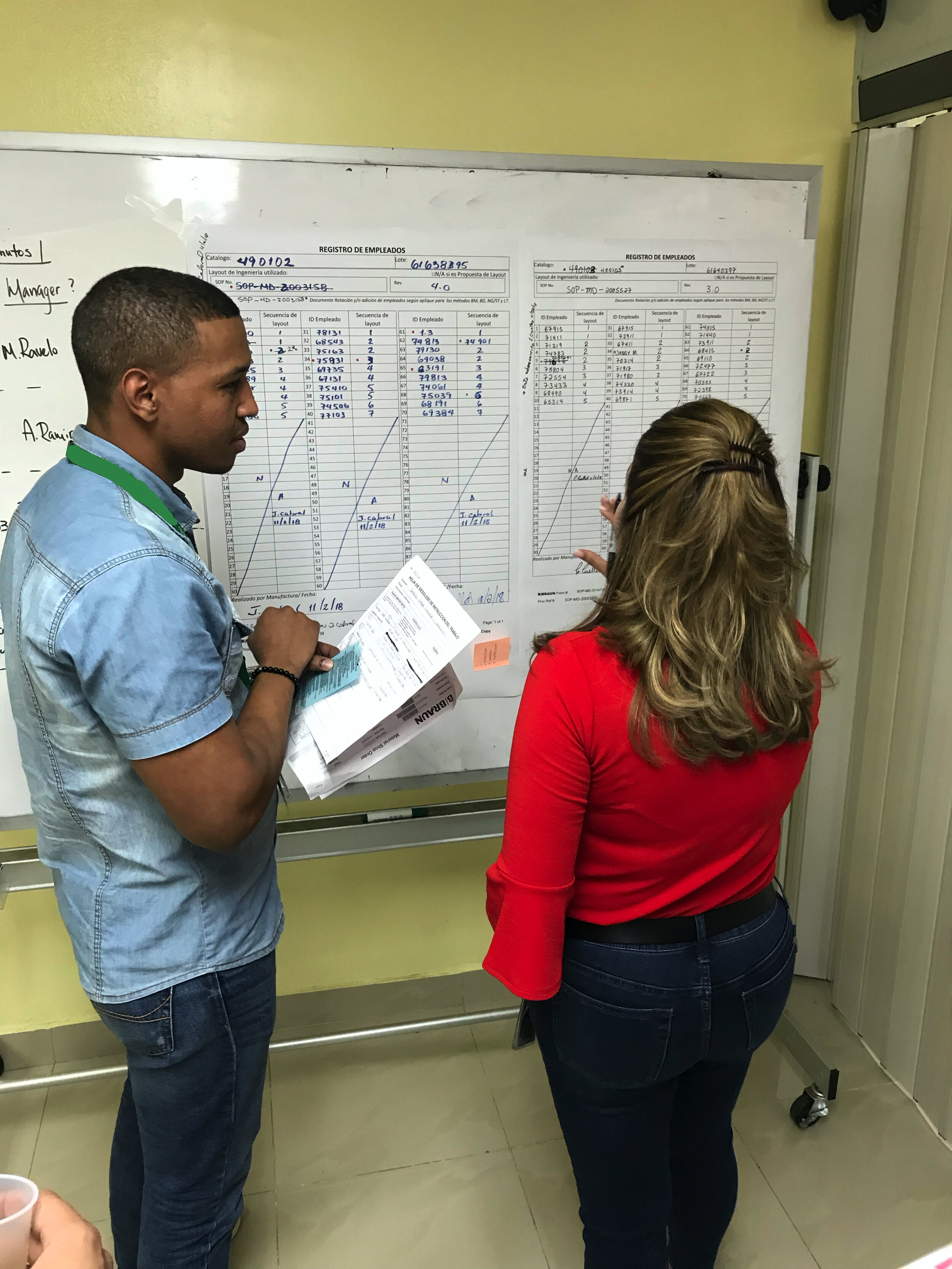

visualise & drive process stabilisation

use visual tools to trigger problem solving when & where it is needed

effective problem solving at levels 1 (containment) & 2 (countermeasure)

Business impact

Through Supervisor Standard Work, organisations can ensure

all activities required to manage production & ensure improvement are carried out correctly and reliably

supervisors & team leaders transition to ‘process focus’ by ‘doing it’

performing the supervisors’ enhanced role becomes easier & less mentally exhausting

the capabilities developed through leadership & improvement skills training get locked in & deliver operating results faster

the pace of Operations Excellence and Lean transformation accelerates